- Qinsun Instruments Co., Ltd.

- Tell:+86-21-6780 0179

- Phone:+86-17740808215

- Address:No. 2578 Minhang District Gu Dai Road, Shanghai

- Contact:Mr. Li

- QQ:846490659

Application of pore structure of activated carbon

Peat based activated carbon has micropores and mesopores, which can be used for various applications;

Lignite based charcoal has more mesopores and larger mesopores, providing excellent accessibility;

Coconut shell based charcoal is mainly composed of micropores and is only suitable for the removal of low molecules.

Activated carbon activated by chemicals is very porous, mostly in the range of micropores and mesopores. However, compared to activated carbon activated by water vapor and activated carbon activated by chemicals, the pore surface of activated carbon activated by chemicals is less hydrophobic and has more negative charges.

Taking extruded and crushed granular activated carbon as examples:

Peat based extruded activated carbon can be made into various varieties with different pore size distributions. Microporous varieties are mainly used for gold recovery in gas-phase applications. Varieties with both micropores and mesopores are mostly used for liquid-phase applications, such as adsorbing impurities from small and large molecules in water purification.

Crushed coal based char has both micropores and mesopores, which can be used for various purposes.

Granular activated carbon based on lignite or coconut shell has the same microporous and mesoporous structure as powdered carbon.

What are the performance indicators of activated carbon?

The performance indicators of activated carbon products can be divided into physical performance indicators, chemical performance indicators, and adsorption performance indicators. The three performance indicators play a very important role in the selection and application of activated carbon.

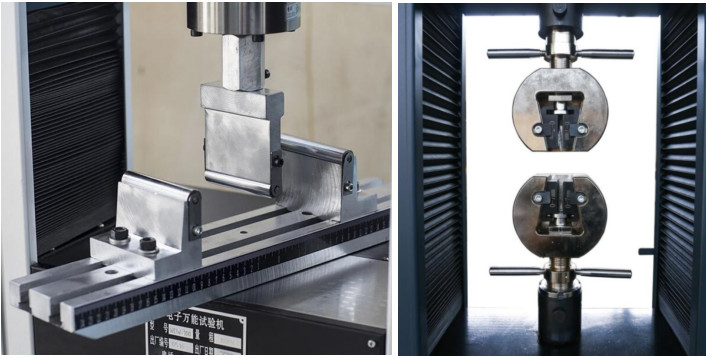

The main physical performance indicators include shape, appearance, specific surface area, pore volume, specific gravity, mesh size, particle size, wear resistance, floating rate, etc.

The main chemical performance indicators include pH value, ash content, moisture content, ignition point, uncarbonized material, sulfide, chloride, cyanide, sulfate, acid soluble material, alcohol soluble material, iron content, zinc content, lead content, arsenic content, calcium and magnesium content, heavy metal content, phosphate, etc.

The main adsorption performance indicators include: methylene blue adsorption value, iodine adsorption value, phenol adsorption value, carbon tetrachloride adsorption value, caramel adsorption value, quinine sulfate adsorption value, saturated sulfur capacity, breakthrough sulfur capacity, water capacity, chloroethane vapor protection time, ABS value, etc.

The main influencing factors of activated carbon water treatment:

Due to the complex adsorption process and principle involved in activated carbon water treatment, there are also many influencing factors. It is mainly related to the properties of activated carbon, the properties of pollutants in water, the process principle of activated carbon treatment, and the selected operating parameters and operating conditions.

The properties of activated carbon

Due to the adsorption phenomenon occurring on the surface of the adsorbent, the specific surface area of the adsorbent is one of the important factors affecting adsorption. The larger the specific surface area, the better the adsorption performance.

Because the adsorption process can be seen as three stages, internal diffusion has a significant impact on the adsorption rate, so the micropore distribution of activated carbon is another important factor affecting adsorption.

In addition, the surface chemical properties, polarity, and charge carried by activated carbon also affect the adsorption effect.

Activated carbon used for water treatment should have three requirements: large adsorption capacity, fast adsorption speed, and good mechanical strength. The adsorption capacity of activated carbon is mainly related to its specific surface area, in addition to other external conditions. With a larger specific surface area and more micropores, there is more adsorbate that can be adsorbed on the walls of the micropores. The adsorption rate is mainly related to particle size and pore distribution.