- Qinsun Instruments Co., Ltd.

- Tell:+86-21-6780 0179

- Phone:+86-17740808215

- Address:No. 2578 Minhang District Gu Dai Road, Shanghai

- Contact:Mr. Li

- QQ:846490659

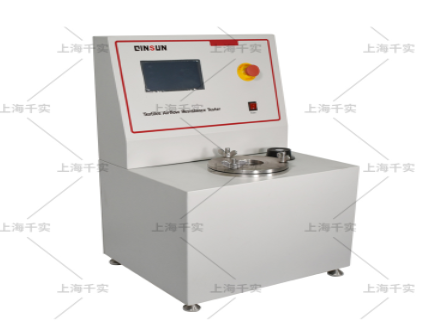

Melt blown fabric | Mask airflow resistance tester

Main use:

The fabric air resistance tester, also known as the medical textile airflow resistance tester, is mainly used to measure the penetration resistance of fabrics, cotton, space cotton, etc. in the air. It can be used to evaluate the comfort and hygiene of clothing, textiles, especially medical textiles. It can be widely used in polymer material production enterprises, printing and dyeing industry enterprises, textile inspection departments, scientific research institutions, textile colleges, etc.

Compliant with standards:

GB 19083-2010

Main parameters:

1. Air flow regulation range: 10L/min-100 L/min (600L/h-6000 L/h)

2. Measurement range of airflow resistance: 0-1kPa

3. Test time: 1 second to 99 hours, optional

4. Power supply: AC220V, 50Hz

5. Overall power: 1.2KW

Main features:

1. The instrument consists of a gas source that can adjust the flow rate, a sample clamping device, and a pressure measurement system;

2. Digital display of airflow resistance, with zero point correction and accuracy correction functions;

3. Easy to operate.

Notes:

1. During the experiment, if the air compressor starts frequently, it indicates significant gas loss, which is a normal situation.

2. If the word "ERROR" appears on the airflow resistance display table after starting the experiment, it indicates that the airflow resistance of the sample has exceeded the set value of 500Pa. The "Test End" button must be immediately pressed to protect the instrument.

3. All parameters of the airflow resistance display table have been set, and non professional maintenance personnel are not allowed to modify them without authorization.

4. The flow meter must be used within the flow range and it is strictly prohibited to use it beyond the range.

5. If too much dust and impurities are found on the rotor inside the flow meter, which affects the reading accuracy, open the back cover plate of the instrument, open the manual ball valve inside the box, and then connect the air source to clean the flow meter. (In normal use, the ball valve inside the box must be in a closed state.)

6. Do not adjust the regulating valve that is not listed in the instrument manual without authorization during the testing process.