- Qinsun Instruments Co., Ltd.

- Tell:+86-21-6780 0179

- Phone:+86-17740808215

- Address:No. 2578 Minhang District Gu Dai Road, Shanghai

- Contact:Mr. Li

- QQ:846490659

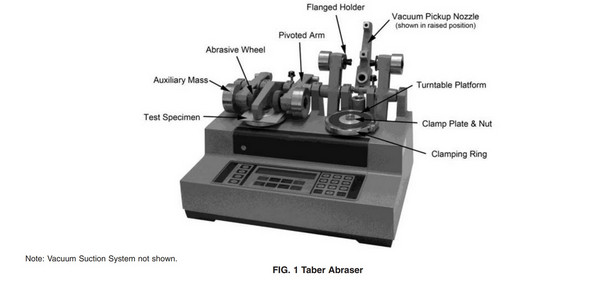

How do I evaluate the surface roughness of a Taber wear test wheel?

The roughness of the test wheel surface is an important factor affecting the results of the Taber wear test, and therefore the roughness of the test wheel surface needs to be evaluated. Two commonly used methods for assessing the surface roughness of test wheels are described below:

Surface Roughness Gauge: A surface roughness gauge is a common tool used to evaluate the surface roughness of a test grinding wheel. It can measure the height difference of the test grinding wheel surface and calculate the surface roughness parameters, such as Ra, Rz, etc., based on the measurement results. For measurement, the probe of the surface roughness measuring instrument needs to be placed on the surface of the test grinding wheel, press the measurement button, and the measuring instrument will automatically scan the surface of the test grinding wheel and display the measurement results of the surface roughness parameters.

Microscope observation: Another way to evaluate the surface roughness of a test wheel is to use a microscope to observe the shape of the test wheel surface. In the observation, the test grinding wheel needs to be placed under the microscope, the magnification and focal length of the microscope is adjusted, and then the roughness and wear of the test grinding wheel surface is observed. By observing the morphology of the test wheel surface, the size and uniformity of its surface roughness can be initially determined.

Regardless of the method used, the following points need to be noted when assessing the surface roughness of the test grinding wheel:

Select the appropriate surface roughness parameters, such as Ra, Rz, etc., according to the testing requirements.

When measuring or observing, you need to ensure that the test grinding wheel surface is clean, flat and free from human interference.

The location of the measurement or observation should represent the overall condition of the test grinding wheel surface as far as possible, and avoid the influence of local special conditions on the evaluation results.

When using the surface roughness measuring instrument, it needs to be operated correctly according to the equipment manual to ensure the accuracy of the measurement results.

In conclusion, evaluating the surface roughness of the test grinding wheel is an important part of ensuring the accuracy and reliability of the Taber wear test results. It is necessary to select the appropriate surface roughness parameters according to the test requirements, choose the appropriate evaluation method and pay attention to the operation specification to ensure the repeatability and reliability of the evaluation results.