- Qinsun Instruments Co., Ltd.

- Tell:+86-21-6780 0179

- Phone:+86-17740808215

- Address:No. 2578 Minhang District Gu Dai Road, Shanghai

- Contact:Mr. Li

- QQ:846490659

How To Make Uv Ageing Test Chamber?

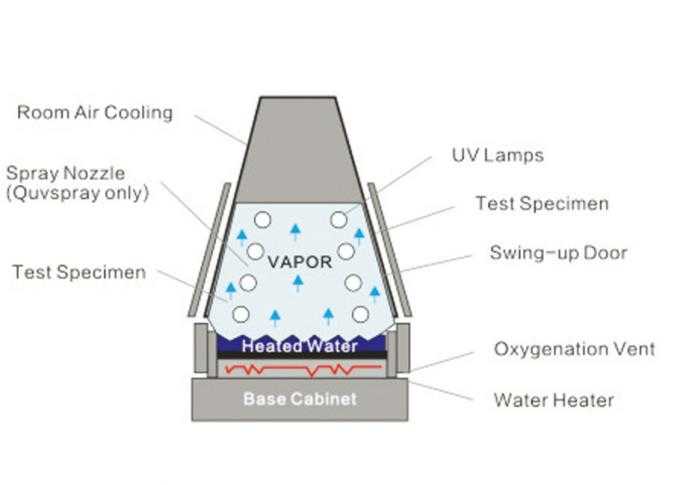

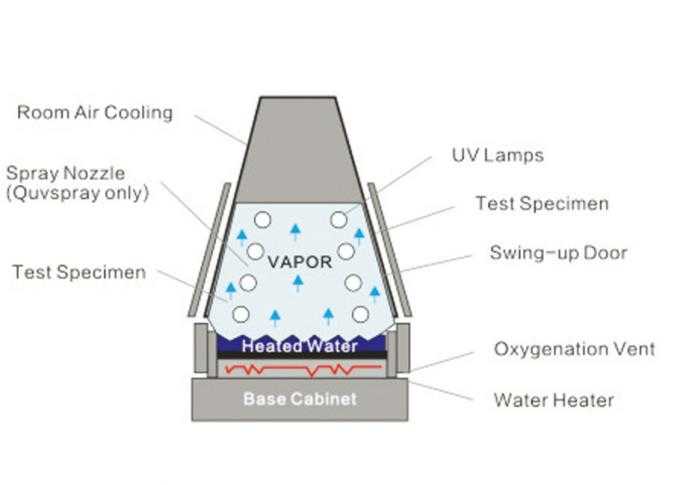

The UV ageing test chamber is a specialized piece of equipment used to simulate the effects of long-term exposure to UV radiation on materials. While the construction of a UV ageing test chamber can vary depending on the specific design, here are some general steps to help you make one:

1.Determine the size of the chamber you need based on the materials you want to test and the testing standards you are following.

2.Choose the UV light source that you want to use. Mercury vapor lamps are the most common type of UV source used in ageing test chambers, but there are also other types available.

3.Build a chamber that allows the UV light to shine on the test material. The chamber should be made of a material that does not interfere with the UV radiation, such as aluminum or stainless steel.

4.Install the UV light source inside the chamber, making sure that it is positioned correctly and securely. The light should be directed towards the test material in a uniform pattern.

5.Install a temperature and humidity control system to maintain the desired testing conditions. This can be achieved by using a heating or cooling system, and a humidity controller.

6.Install a timer or a controller to set the duration of the test.

7.Calibrate the chamber to ensure that it is providing the correct UV radiation intensity and temperature/humidity conditions for the test.

It is important to note that the construction and calibration of a UV ageing test chamber can be complex and should only be carried out by qualified professionals.