- Qinsun Instruments Co., Ltd.

- Tell:+86-21-6780 0179

- Phone:+86-17740808215

- Address:No. 2578 Minhang District Gu Dai Road, Shanghai

- Contact:Mr. Li

- QQ:846490659

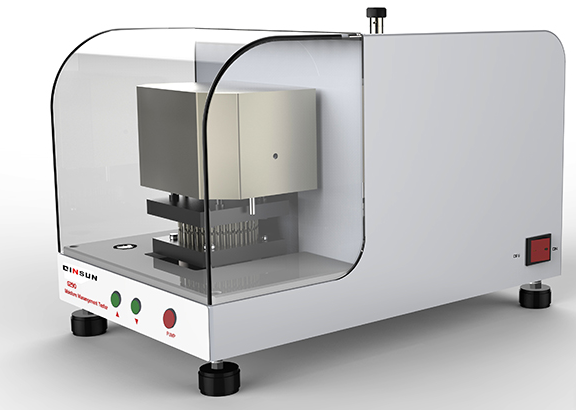

Liquid moisture management tester

Applicable scope:

Dynamic transfer characteristics of moisture in knitted and woven fabrics, testing and evaluation of moisture absorption and rapid drying performance of sports fabrics.

Compliant with standards:

AATCC 195 SN 1689.1 GB/T 21655.2

Testing principle:

The Liquid Moisture Management Tester (MMT Test) mainly tests the absorption and diffusion performance of sweat in fabrics. The absorption and diffusion of sweat by fabrics directly affect the comfort of clothing wearing. To improve the comfort of clothing (especially sportswear fabrics), it is crucial to test the liquid moisture management ability of fabrics, which helps to evaluate the moisture absorption and drying performance of textiles and improve material properties. The liquid moisture management tester is used to measure the overall dynamic performance of liquids in knitted and woven fabrics. It tests the absorption speed (water absorption time on the front and back of the fabric), one-way transmission ability (difference in absorption and diffusion of liquids on both sides of the fabric), and diffusion/drying speed (diffusion speed of liquids on both sides of the fabric). The liquid moisture management tester includes

an upper and lower concentric liquid sensor with multiple probes. The infusion tube in the upper sensor uniformly drips a fixed concentration of saline solution that simulates human sweat onto the fabric. The sensor probe tests the resistance between different rings to reflect the absorption and diffusion of the liquid on the fabric, thereby obtaining the fabric's ability to absorb and diffuse sweat.

MMT Test can measure the following parameters:

1. Soaking time of upper/lower layers;

2. Upper/lower layer sweat absorption speed;

3. Maximum diffusion radius of upper/lower layers;

4. Sweat diffusion rate of upper/lower layer liquid;

5. Accumulate one-way transmission capability;

6. Overall liquid water absorption and diffusion capacity.

Technical features:

1. The all metal shell has excellent anti-interference performance;

2. Start the test with one click. After clicking the start button, the motor automatically drives the test head to the specified position, with a built-in pressure detection device. When the pressure is fixed, it automatically stops and starts the test. After the test is completed, it automatically returns;

3. Improved droplet injection system, precise and stable dripping; The unique reverse pumping system can rotate in the opposite direction to pump the remaining salt water from the infusion tube back into the water storage tank, preventing salt water crystallization from blocking the pipeline.

Product configuration:

1. Host

2. Analysis software

3. Conductivity tester