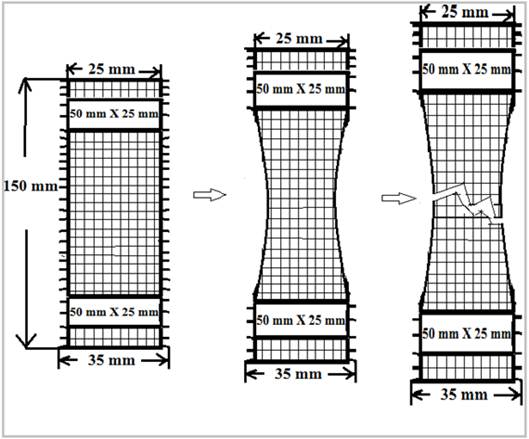

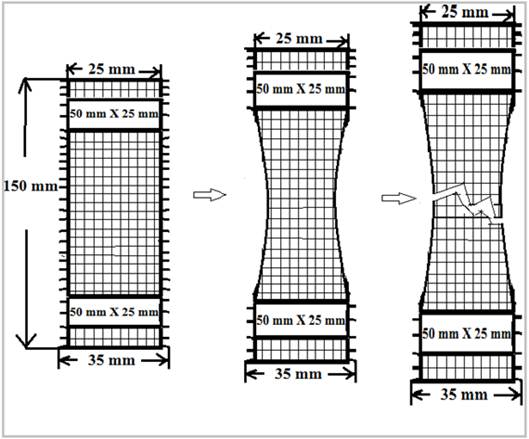

When a fabric is under uniaxial or biaxial tension, the yarn-yarn interactions at the crossing points are found to consist of two components, a pressure-independent adhesive component and a pressure-dependent frictional one, of which the latter is proved to be dominant. On the basis of the analysis, the yarn critical length in the fragmentation process during fabric extension is defined and calculated.

Moreover, by treating the fabric as an assemblage of yarn bundles, the distribution density function of the strengths between individual yarns in the same bundle is provided based on the single yarn strength distribution, and the fracture process of the bundle can be better described using this function.

The strength tests covered in this section include tensile, tear, seam and burst strength. These mechanical properties arc important for all textile users including fabric processors, garment manufacturers, designers and customers.

The strength of a fabric gives us an idea how much load we can apply on it and it is very important for fabric. The strength of the fabric is very necessary for it because if the fabric strength is not good then it will break with excessive tensile force and thus the dresses produced may tear with the outside force. The strength of a fabric varies with EPI, PPI, and Count Variation. The strength of the fabric also varies if the length and width of the fabric to be tested is changed. The strength of the fabric also depends on the construction of the fabric. A plain fabric is stronger than a twill fabric if made from yarn of same count.