- Qinsun Instruments Co., Ltd.

- Tell:+86-21-6780 0179

- Phone:+86-17740808215

- Address:No. 2578 Minhang District Gu Dai Road, Shanghai

- Contact:Mr. Li

- QQ:846490659

How to conduct Taber Abrasion Test?

Taber wear resistance test is a commonly used method for testing the surface wear resistance of materials, mainly used to test the surface wear properties of plastics, metals, coatings, paper, textiles and other materials. Before carrying out the Taber wear resistance test, it is necessary to read the relevant test standards and instructions carefully to ensure the accuracy and repeatability of the test results. The following are the detailed steps to conduct the Taber wear resistance test:

Prepare the sample: According to the test requirements, cut the material sample into the appropriate shape and size, usually round or square. The samples are then cleaned to ensure that their surfaces are free of impurities and dirt.

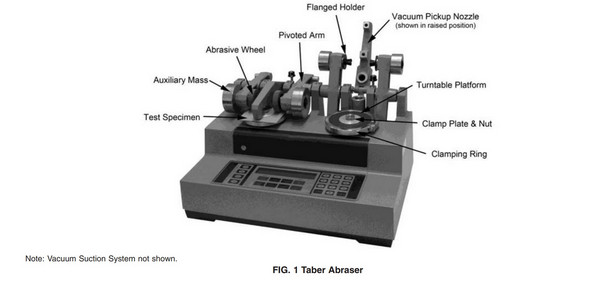

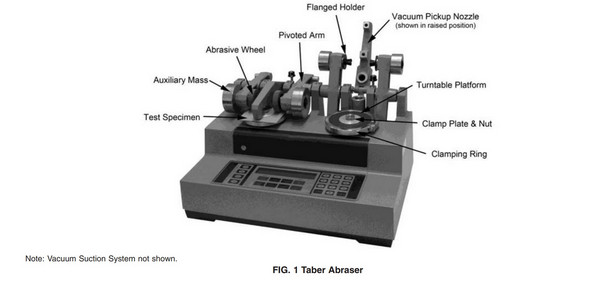

Prepare the testing instrument: place the Taber wear testing machine on a horizontal platform, select the appropriate test grinding wheel and load according to the test requirements, and install it on the testing machine.

Adjust the parameters of the testing machine: According to the test requirements, adjust the parameters of the testing machine, such as speed, test time, load, etc. When adjusting the parameters of the testing machine, it is necessary to pay attention to selecting the appropriate test parameters to ensure the accuracy and repeatability of the test results.

Install the sample: Install the sample on the testing machine and fasten it. When mounting the sample, it is necessary to ensure that its surface is in contact with the grinding wheel and is as flat as possible.

Start the testing machine: start the testing machine according to the operating instructions of the testing machine, and set the test time or wear amount according to the test requirements. During the test, the wear condition of the sample can be recorded in due course.

End the test: When the test time or wear amount reaches the set value, stop the test and remove the sample from the testing machine.

Analyzing data: According to the test results, the wear conditions of the samples can be analyzed and compared using microscopes, photography and other methods to evaluate their surface wear resistance.

It should be noted that the parameter settings and test methods of the Taber abrasion tester will vary with different materials and application fields. Therefore, before conducting the Taber wear test, it is necessary to read the relevant test standards and instructions carefully to ensure the accuracy and repeatability of the test results. At the same time, it is also necessary to pay attention to safety issues during the test, such as avoiding personal injury or equipment damage caused by operating errors.

The following are some commonly used Taber wear test parameter settings and test methods:

Parameter setting: According to the test requirements, select the appropriate test grinding wheel and load, usually choose H-18 grinding wheel and 1 kg load. The test time is generally 1000 reciprocating movements, and the distance of each reciprocating movement is 12.7 mm.

Sample preparation: According to the test requirements, the sample is cut into a circle or a square, and its surface is polished to eliminate surface defects and dirt.

Test method: install the sample on the testing machine, and adjust the parameters of the testing machine according to the test requirements. Start the testing machine, make the test grinding wheel contact with the surface of the sample, and start the wear test. During the test, the wear condition of the sample can be recorded timely, such as weight loss, depth, etc.

Analyzing data: According to the test results, the wear conditions of the samples can be analyzed and compared using microscopes, photography and other methods to evaluate their surface wear resistance. Usually wear index (Wear Index) and wear rate (Wear Rate) and other indicators are used to evaluate wear performance.

In addition to the above commonly used Taber wear test parameter settings and test methods, there are some other parameters and test methods that deserve attention, such as:

Selection of test grinding wheel: factors such as the type of test grinding wheel, hardness and surface roughness will affect the test results, so it is necessary to select a suitable test grinding wheel according to the test requirements.

Selection of load: The size of the load directly affects the degree of wear of the sample, so it is necessary to select the appropriate load size according to the test requirements.

Selection of test time and reciprocating distance: The test time and reciprocating distance will also affect the test results, so it is necessary to select the appropriate test time and reciprocating distance according to the test requirements.

Repeatability and repeatability control: The repeatability and repeatability of the Taber wear test is crucial to the accuracy and reliability of the test results, so it is necessary to strictly control the test conditions and operating procedures during the test to ensure the test results repeatability and comparability.

In conclusion, the Taber wear test is a simple and effective method for testing the wear resistance of the material surface, and has a wide range of application values. Before conducting the Taber wear test, it is necessary to carefully read the relevant test standards and instructions, and select the appropriate test parameters and test methods to ensure the accuracy and repeatability of the test results. At the same time, it is also necessary to pay attention to safety issues during the test, such as avoiding personal injury or equipment damage caused by operating errors.