- Qinsun Instruments Co., Ltd.

- Tell:+86-21-6780 0179

- Phone:+86-17740808215

- Address:No. 2578 Minhang District Gu Dai Road, Shanghai

- Contact:Mr. Li

- QQ:846490659

Do you know the TABER Abrasion Test?

The TABER wear test is a widely used method for evaluating the wear resistance of materials and surface coatings. It is used to simulate real-world wear and friction conditions by using the TABER wear tester to determine a material's resistance to wear under specific conditions.

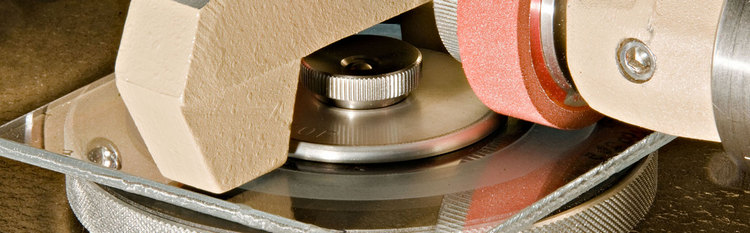

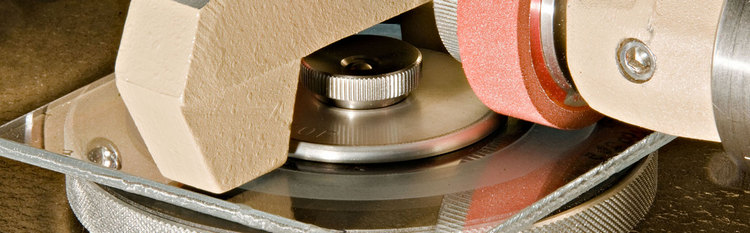

The TABER wear tester consists of a rotating disc and a loaded sample. The disc has a wear head attached to it, which allows specific pressure and wear forces to be applied by weighting the load and adjusting the speed of rotation. The sample is placed on the disc, and as the disc rotates, friction and wear occurs between the sample and the wear head.

Common indicators used in TABER wear testing include:

1. Weight Loss: Used to assess the degree of mass loss of a material during testing, usually in milligrams or grams.

2. Wear Index: A measure of the wear resistance of a material. The index is based on the amount of wear on the surface of the sample. By comparing the wear indices of different samples, their relative wear resistance can be determined.

3. Haze value: It is used to evaluate the degree of wear of transparent or translucent materials. It measures the degree of scattering due to wear as light propagates through the material.

The TABER abrasion test is commonly used to evaluate the abrasion resistance of various materials and coatings, such as plastics, metals, coatings, glass, paper, textiles, etc. It is widely used in many industries, such as automotive manufacturing, furniture manufacturing, construction materials, aerospace, etc. By performing the TABER abrasion test, it helps manufacturers to understand the durability and performance of materials so that they can select the right material and perform quality control.