- Qinsun Instruments Co., Ltd.

- Tell:+86-21-6780 0179

- Phone:+86-17740808215

- Address:No. 2578 Minhang District Gu Dai Road, Shanghai

- Contact:Mr. Li

- QQ:846490659

7 Tips for Operating Zipper Testing Equipment

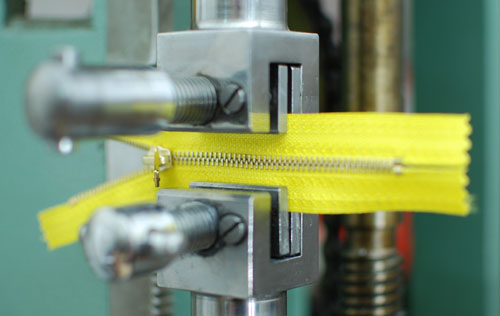

Zippers are a common garment accessory, and their quality and performance directly affect the overall effect and service life of the garment. Therefore, it is essential to test zippers. Zipper testing equipment is a special instrument used to test the strength and durability of various zippers. It can simulate various stresses on the zipper in actual use and evaluate the reliability and safety of the zipper. This article will introduce 7 tips for operating zipper testing equipment to help you improve testing efficiency and accuracy.

1. Choose the right test items and standards. There are different test items and standards for different types of zippers, such as metal zippers, plastic zippers, nylon zippers, etc. You should choose the right test items and standards according to the material, structure, specification and usage of the zipper you want to test, to avoid using inapplicable or too harsh standards that may cause waste or misjudgment.

2. Prepare the test sample. You should intercept a certain length of sample from the whole zipper, usually 75mm-100mm, to ensure that the sample is intact and free from stains, creases, deformation and other factors that may affect the test results. You should also park the sample in the laboratory environment for more than 8 hours to adapt it to the temperature and humidity and other conditions to avoid environmental factors from interfering with the test results.

3. Adjust the test equipment. You should set the parameters of the test equipment, such as speed, load, number of cycles, etc., according to the test items and standards. You should also check that the test equipment is working properly and is not faulty or damaged to ensure that the testing process is carried out smoothly.

4. Install the sample correctly. You should properly mount the sample on the test equipment so that the sample is closely aligned with the fixture and not loose or skewed, as required by the test item and standard. You should also take care to protect the sample from damage or deformation during the mounting process.

5. Start the test and record the data. You should start the test equipment after confirming that the sample is installed correctly and observe the test process, recording the test data and damage status. You should also pay attention to find and deal with abnormal conditions, such as equipment failure, sample dislodgement, etc., in time during the test to prevent affecting the test results.

6. Calculate and analyze the results. You should calculate and analyze the test data and derive the test results according to the requirements of the test items and standards. You should also compare the results between different samples to identify possible problems or discrepancies and give reasonable explanations or suggestions.

7. Clean and maintain the equipment. You should clean and maintain the test equipment after completing the test to remove dust, oil, and other debris left on it to prevent rust or damage to the equipment. You should also regularly inspect and repair the equipment to keep it in good working condition.